Rubber Flooring Costs

A common question asked of shoppers is, “How much do rubber floors cost?” While each project is unique and many factors can impact the final cost of rubber floors, prices will typically vary based on the type of rubber flooring, the thickness, the color selected, and the quality of the material used during production.

It’s important to note that for budgetary purposes, the product cost may also include additional costs, including installation fees, subfloor preparation, adhesive, sealant, and removal of existing flooring, as required. In this guide, we will focus on three main aspects that can heavily impact the rubber flooring product cost on any project: rubber floor type, thickness, and quality.

Type of Rubber Flooring

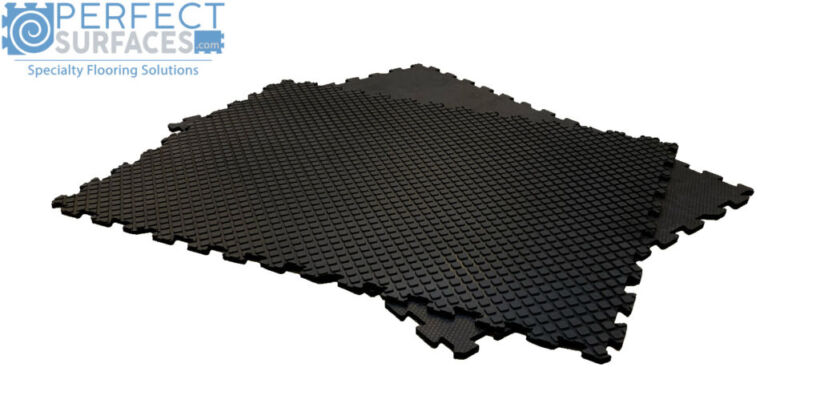

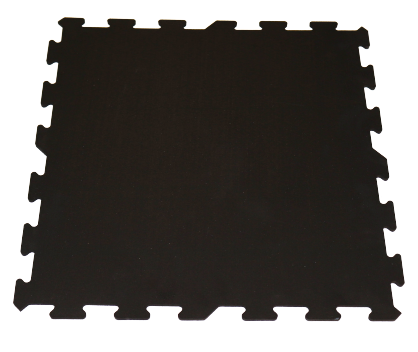

The three most common formats to choose from when drafting a budget and picking the right floor for your space are rubber interlocking tiles, rubber sheets/mats, and rolled rubber flooring. Perfect Surfaces offers flooring products suitable for a range of budgets and easy to install for professionals and DIY enthusiasts alike.

When considering the format to choose, from a strictly cost perspective, rubber rolls are commonly the most cost-effective option per square foot, followed by interlocking tiles, with rubber mats coming in at the higher end of the rice range. Prices may vary between projects based on the coverage, wastage, color, thickness, and quality of the product used. For assistance choosing the right flooring type for your project, contact the Perfect Surfaces rubber flooring experts to confidently choose the best product for your budget and design requirements.

Thickness and Color of the Flooring

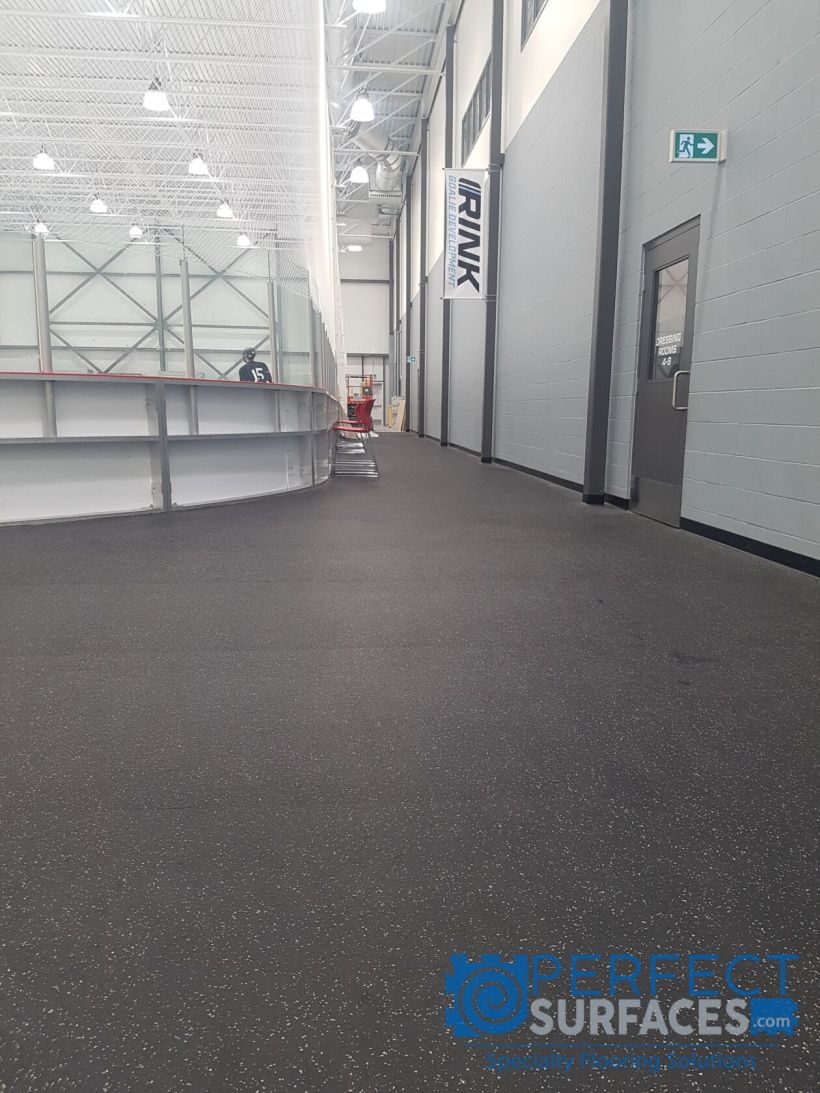

The thickness of rubber flooring can significantly affect the product price. Typically, the thicker the rubber, the more expensive it gets. Despite the price point, thicker rubber flooring is generally preferred for high-traffic areas such as commercial gyms and daycares due to its long-lasting durability. Selecting the right rubber flooring, based on how you plan to use the space, is key to a long-lasting, high-performing rubber floor.

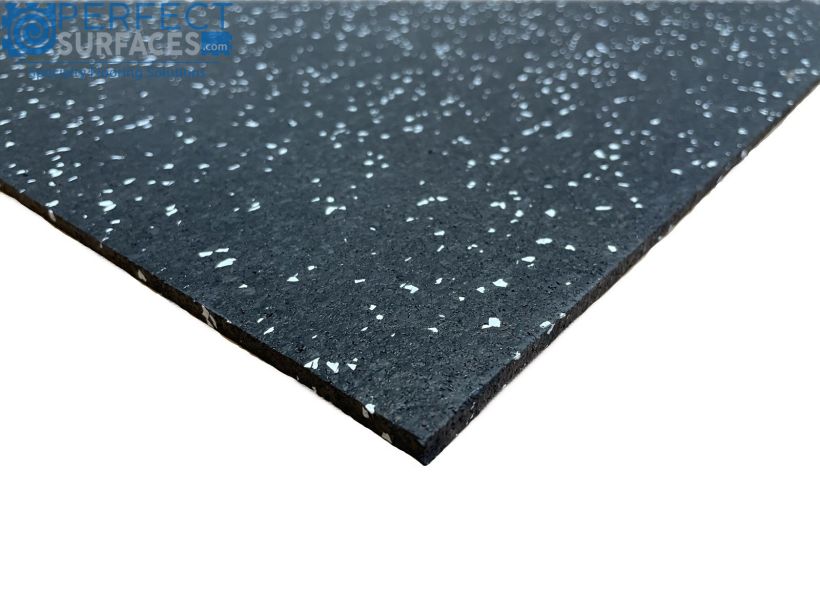

Another important factor that can influence the price of rubber flooring is its color. Most recycled rubber floors are produced as solid black flooring or black with speckled color content. These are generally more cost-effective options compared to non-recycled Virgin EPDM rubber floors. Contact the rubber floor experts at Perfect Surfaces to help you choose the best thickness and color to suit your budget and space.

Quality and Brand

The chemicals, materials, and bonding process used during rubber floor production impact its quality. Urethane rubber can withstand high loads, greases, and oils and is great for high-impact areas. Perfect Surfaces offers both urethane-bonded and vulcanized rubber products.

What sets vulcanized rubber apart is its non-porous nature, moisture resistance, finished appearance, and smoother finish texture. These features make it easier to maintain and give it a nicer finished appearance. Depending on how you plan to use your space, our experts can help you choose the best quality floor for your budget.